Today’s digital business landscape has made it easier and faster for customers to find and make their purchase from anywhere and anytime. This is great for business, since they no longer need to invest more in brick-and-mortar stores and can instead keep all products in warehouses, to be picked up and dispatched directly to the customer when needed; however, given the operation speeds demanded in this setup, it means that businesses have to better their warehousing storage models and find ways to streamline their entire process, and do it smartly.

A lot has been written and spoken about inventory management; there are articles, discussions and white papers on this subject. What gets less attention is storage space slotting. This is rather unfortunate since nothing impacts warehouse operations and efficiency as much as the right slotting techniques.

To explain it in simple terms, storage space slotting is the science (and art, for some) of placing and storing products in a warehouse in the most efficient way possible. The aim is to minimize space wastage while also taking into account product needs and picking paths.

Let’s understand the objectives behind the right storage slotting

Better storage slotting becomes important when a business starts to find its existing storage space insufficient for the SKUs that it needs to stock at any given point. Larger number of products means a longer travel path for picking. The right slotting technique can make great inroads in enhancing warehouse operations.

For this it needs to:

c.Optimize spaces in the warehouse

d.Reduce handling cost

How does a business decide its slotting strategy?

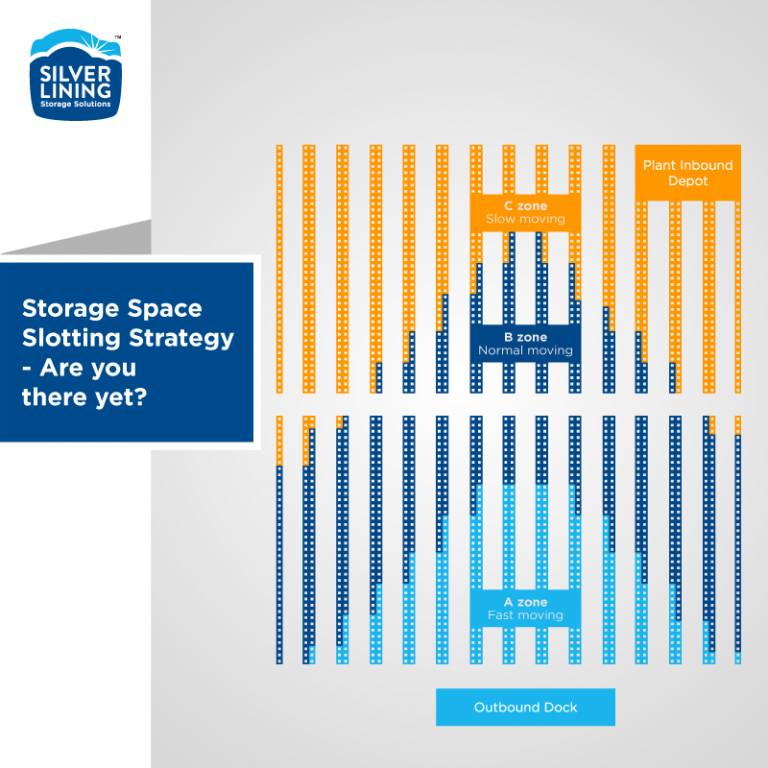

A storage slotting strategy will vary from business to business, from product to product, as well as customers. Choosing the right approach plays an important role in the warehouse’s productivity and costs. Done right, slotting aims to maximize the use of the cube space available and to reduce travel time.

You can base your slotting strategy on numerous factors, such as:

> Product velocity: Products that move faster and are in high demand are placed closest to dispatch to save travel time and for better ergonomics.

> Seasonal usage: A product can be moved to the high velocity area during its high-volume season and shifted back to a less prime area the rest of the year. Recognizing the right season for the product plays a large role in the slotting strategy.

> Storage/ Pick types: When similar sized goods or pallets are placed together, it saves travel and pick time for material handling equipment.

> Special product characteristics: Does the warehouse stock products that require special handling or storage environment? These factors should be taken into consideration when formulating the storage slotting strategy.

> Product similarity: Products that are often ordered together or are similar can be slotted together for improved efficiency. But, necessary care should be taken to avoid picking errors.

Customer base: Grouping products as per customer base/segmentation can improve picking speeds and overall warehouse efficiency.

> Product loading/ layout: Products that are slotted according to loading sequence or delivery routes can help improve performance.

What are the advantages of storage space slotting?

With storage space slotting, a business is empowered to offer its customers what they want, when they want, and more efficiently. Which business would say no to that? Here are the top benefits of storage space slotting:

1. Picking productivity

In the absence of strategic storage space slotting, warehouse employees spend a lot of time traveling and searching for products. Typically, a picker’s time is spent:

55% in traveling through the warehouse

15% in searching for the product location

20% while waiting in queue

10% in actually pulling products from locations

Depending on the storage strategy deployed, a business will be better equipped to improve picking productivity. There is lesser product handling as well.

2. Picking accuracy

A warehouse is required to be fast. However, in the face of meeting delivery times, accuracy suffers. With storage space slotting, some typical sources of mistakes can be eliminated. For instance, ensuring similarly wrapped products are not placed together, or products with similar characteristics are not adjacent to each other. Reduced confusion will lower the error rate drastically, and improve accuracy.

3. Replenishment efficiency

A slotting strategy ensures that every product has a pre-decided spot and the slots are made to order as per specific product dimensions. This reduced the laborious time and effort required during replenishment, and there is no guesswork involved.

4. Optimises space

The right slotting strategy takes into account the entire cube space of the warehouse, thus ensuring minimal wastage. This strategy also requires fewer pallets.

5. Reduced damage

Products are placed appropriately, as per their definition of ‘heavy’ or ‘fragile’. Thus, picking and retrieving is accurately done as well.

6. Ergonomics and safety

Slotting ensures better ergonomics. High moving goods are placed at waist level, reducing work-related accidents or injuries. Warehouse operators are also happier and more productive.

7. Workload balancing

With storage space slotting comes complete knowledge of product movement cycles. When warehouse managers are aware of high, medium and low moving items, specifically their respective bin positions, work can be distributed equally among all warehouse operators.

Remember, storage space slotting is a dynamic process. As products and customers change, so must the storage space slotting strategy. A warehouse must conduct regular reviews to check whether the current strategy is enabling it to utilize its potential fully.

Pit your strategy against your current and expected business requirements, and your storage space slotting initiative will give your resultant increase in productivity and efficiency.

Do write to us about issues concerning your current warehouse storage space optimization.

Topics: Warehouse Storage Layouts, Warehouse Optimization, Warehouse Operations